The supply chain world is buzzing with excitement about AI-powered demand forecasting tools. Every vendor promises the same thing: "Our AI will make your forecasts 90% more accurate!" But here's the uncomfortable truth that most consultants won't tell you:

Adding AI to a broken MRP system is like putting a Ferrari engine in a horse-drawn carriage.

The Precision Paradox

Let me paint a picture that probably feels familiar. Your company just invested in a next-generation AI demand planning tool. The demos were impressive machine learning algorithms that can detect patterns in historical data that humans could never spot. The forecasts look more sophisticated than anything you've seen before.

But three months later, you're still dealing with:

- Rush orders that appeared out of nowhere

- Excessive inventory in some areas, stockouts in others

- Planners spending their days in firefighting mode

- A nervous CFO asking why working capital keeps climbing

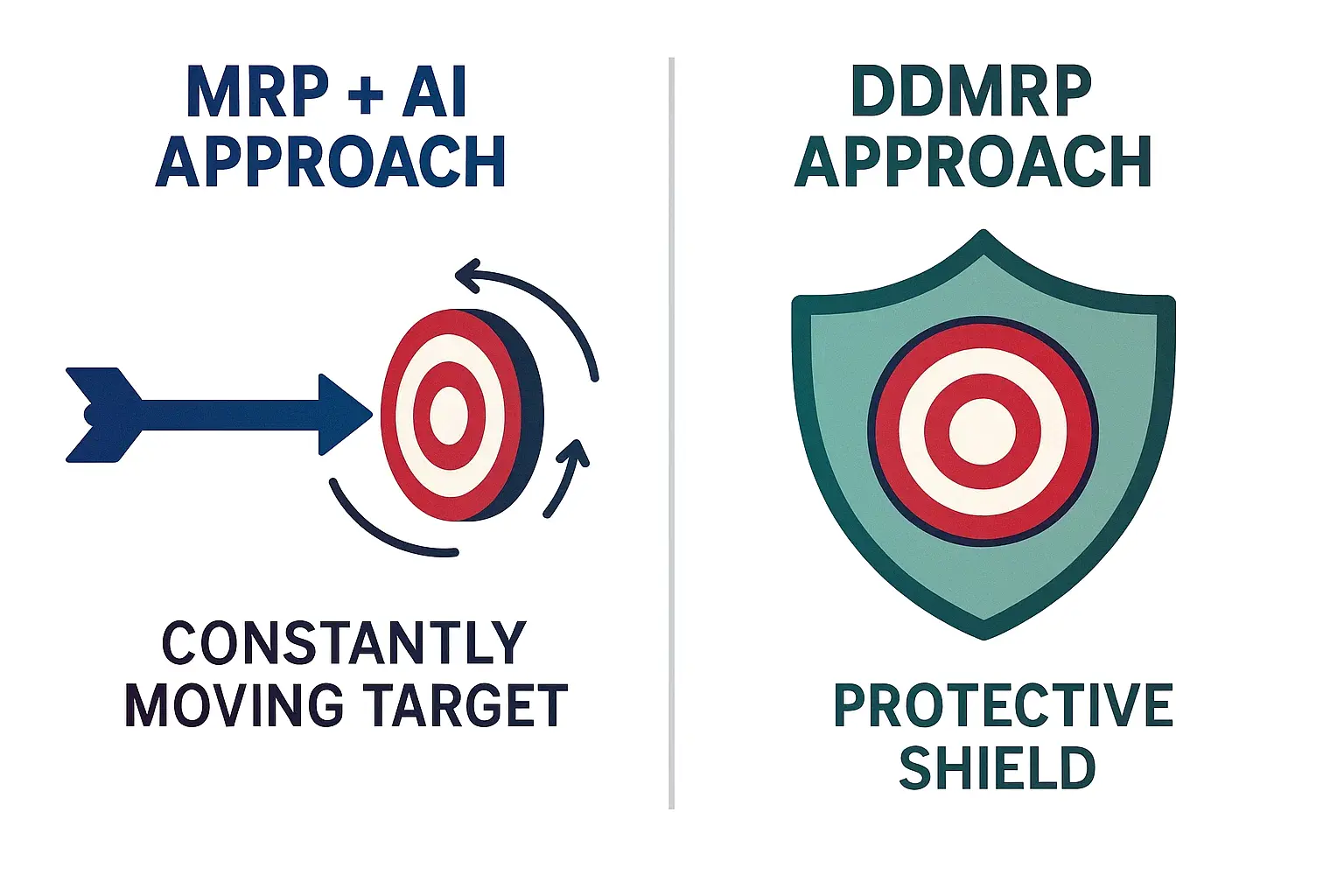

Sound familiar? That's because you're still trying to hit a moving target with a precision rifle instead of building a protective shield around variability.

The Fundamental Flaw in MRP + AI Logic

Here's what conventional wisdom tells us: "If we can just forecast demand more accurately, everything will fall into place."

This thinking is fundamentally flawed for one simple reason: variability isn't a problem to be solved – it's a reality to be managed.

Traditional MRP systems, even those enhanced with AI, operate on a critical assumption: that we can predict and plan for the future with enough precision to optimize our entire supply chain. But in today's volatile market environment, this assumption breaks down faster than a chocolate teapot in a sauna.

DDMRP: Building Shields, Not Seeking Precision

This is where Demand Driven Material Requirements Planning (DDMRP) changes the game entirely. Instead of trying to predict the unpredictable with surgical precision, DDMRP creates what I call Variability Shielding.

The core philosophy is beautifully simple: position strategic inventory buffers at the right points in your supply chain to absorb demand and supply variability, while dramatically shortening your response times to actual market signals.

The DDMRP Advantage: Flow Over Forecasts

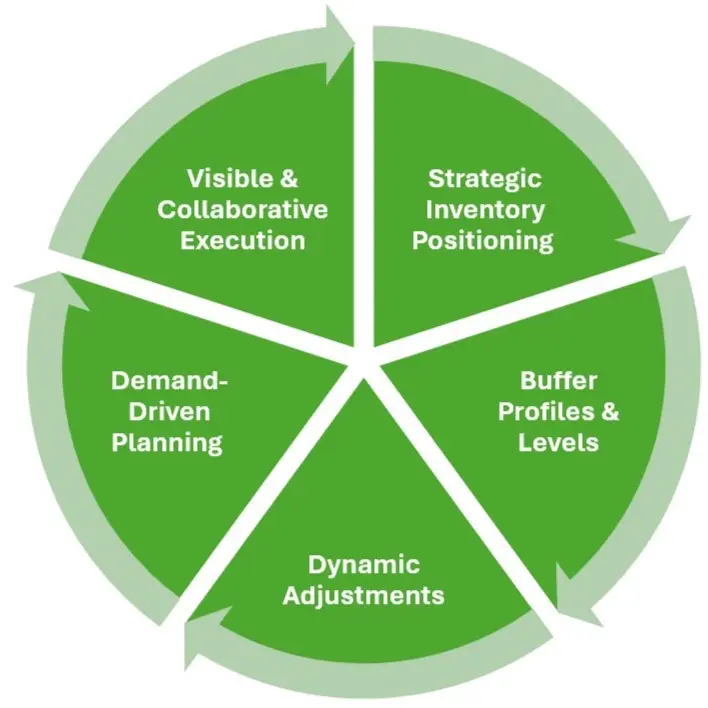

DDMRP operates on five fundamental components that work together to create a truly demand-driven system:

1. Strategic Inventory Positioning: Instead of guessing where inventory should be, DDMRP uses systematic criteria to determine optimal decoupling points

2. Buffer Profiles and Levels: Creates Variability Shielding that's right-sized for each item's characteristics

3. Dynamic Adjustments: Continuously adapts buffer levels based on actual market signals

4. Demand-Driven Planning: Generates supply orders based on actual consumption, not forecasted demand

5. Visible and Collaborative Execution: Provides clear priorities and alerts for day-to-day operations

Real Talk: Where AI Actually Helps in DDMRP

Now, before you think I'm completely anti-AI, let me be clear: AI has a valuable role in a demand-driven system – it's just not what most vendors are selling you.

In DDMRP, AI can excel at:

- Optimizing buffer calculations based on complex variability patterns

- Detecting trends that should trigger dynamic buffer adjustments

- Improving long-term capacity planning (not day-to-day replenishment)

- Identifying optimal decoupling points through network analysis

The key difference? In DDMRP, AI operates within a system designed to handle variability gracefully, rather than trying to eliminate it entirely.

The Bottom Line: Protection Beats Precision

Companies implementing DDMRP typically see:

- 30-50% reduction in inventory while improving service levels

- Dramatic reduction in expedite costs and firefighting

- Shorter, more predictable lead times through strategic decoupling

- Improved cash flow from better working capital management

These results don't come from more accurate forecasts – they come from building adaptive resilience directly into your supply chain.

Making the Transition: Start with Thoughtware

If you're ready to move beyond the precision trap and embrace protective planning, the journey starts with what DDMRP calls "thoughtware" – understanding where and how to strategically position your Variability Shielding.

This isn't about throwing out your existing systems overnight. It's about reimagining how you use them to create flow rather than fight variability.

Your Next Steps

The supply chain world doesn't need more complexity – it needs more intelligence about how to handle complexity. DDMRP provides that intelligence through proven methodologies that thousands of companies worldwide have successfully implemented.

Stop trying to predict the unpredictable. Start building systems that can adapt, protect, and perform regardless of what variability throws at you.

Ready to escape the precision trap and build real supply chain resilience? Let's discuss how DDMRP can transform your planning approach. The conversation starts with understanding your current challenges – not selling you another complex solution.

About the Author: Vincent Kuiper is a supply chain professional who is APICS CPIM and Demand Driven Planner certified, specializing in Demand Driven transformations, dedicated to helping businesses unlock new levels of efficiency and agility. He believes that smart planning isn't just good for business; it's essential for a sustainable future.